RESINOUS FLOORING

Resinous flooring involves applying a base of resinous material to concrete, creating a smooth, non-porous flooring surface. Resinous flooring is typically cast or poured in place then is cured, allowing it to set completely. These flooring systems can be decorative and are very chemical resistive.

3 MATERIALS OF RESINOUS FLOORING

The 3 most common types of resinous flooring are epoxy, polyurethane, and acrylic. All three are two-part systems consisting of a resin and a hardener material. The two parts are mixed just prior to application, and a chemical reaction between them causes the mixture to begin hardening immediately.

HIGHLY USED RESINOUS FLOORING SYSTEMS

THIN MIL

For light traffic applications, Thin Mil Floor Coatings are high performance floor products that offer excellent abrasion resistance and adhesion, making them ideal for hundreds of applications. They are noted for their attractive appearance, chemical resistance and are easy to clean.

HIGH BUILD

For heavy traffic application, these systems can be used in warehouses, distribution facilities, dealership parts rooms, aircraft hangars and other medium duty areas.

These high build floor systems can be used for floors that are too rough for thin mil floor systems but not damaged enough for the Heavy Duty Resurfacer or floors that require specialty coverage.. The floor system is applied at a heavy mil thickness and cures to an extremely durable surface. Topcoats are optional and can be applied depending on floor usage and other special requirements.

MORTAR

Heavy duty Epoxy Mortar Systems repair moderate to severely spalled, pitted or otherwise deteriorated concrete floors. They provide sanitary, skid-resistant and highly impact resistant surfaces, exhibiting impressive compressive strength and point-load capacity.

BENEFITS OF RESINOUS FLOORING

CHEMICAL RESISTANT: Proper protective coatings can help prevent solvents, acids, alkalis, and other compounds from absorbing into the concrete and seeping into the soil underneath.

SEAMLESS SURFACE: Provides a smooth seamless surface that blocks dirt, grime, and bacteria from building up. Perfect for facilities where hygiene is a top priority.

SLIP RESISTANT: Back of house work and food and beverage processing areas require a floor with slip resistance. Anti-slip and slip resistant textures can be installed in the epoxy system.

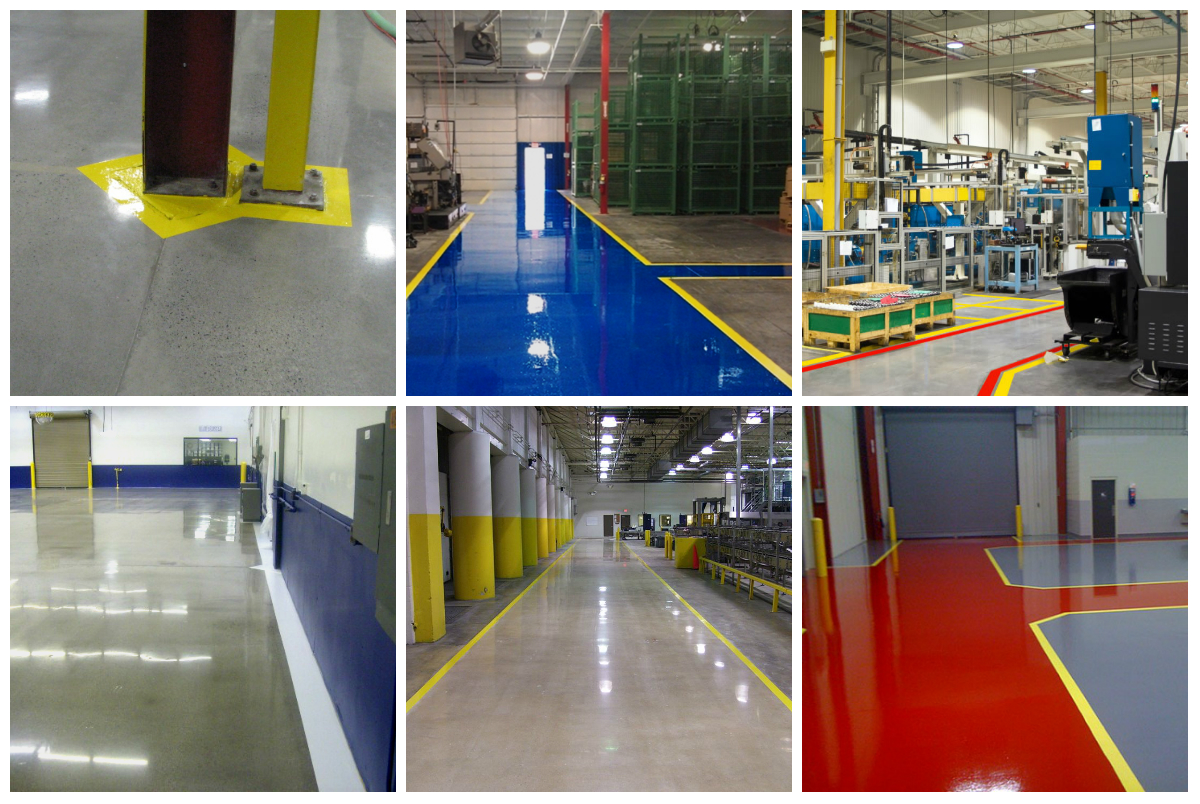

HEAVILY CUSTOMIZABLE: Coatings come in an array of colors and can be patterned to fit your specific style.

ABILITY TO FIT IN TIGHT SPACES: Unlike other floor systems resinous flooring can be poured in areas where equipment or manufacturing lines cannot be moved.

HARD WEARING: Very durable floor system that can withstand large amounts of heavy machinery traffic.

BORDER PAINT & LINE STRIPING